Plastic Injection Molding

40+ years of experience

ITAR Registered

ISO9001: 2015 Certified

COMPREHENSIVE CUSTOM INJECTION MOLDING SERVICES

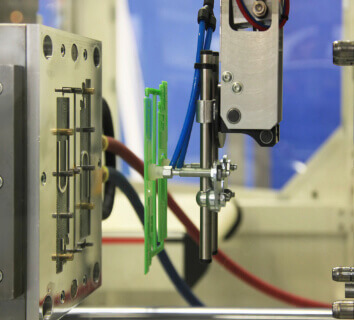

TenX Manufacturing provides a comprehensive approach to injection molding for our customers. Beginning with a design for manufacturability (DFM) assessment and mold flow analysis, our team can provide critical feedback to ensure success of the molded parts. With in-house tooling capabilities TenX can save time and costs for our customers.

Toolmaking & Injection Molding at TenX

Our Tool Makers work closely with our Process Engineers from tool design, all the way to first off molded part samples and throughout production. TenX utilizes state-of-the-art equipment to provide the highest quality injection mold tooling and molded parts, including: prototyping, low-volume production, and multi-cavity high volume production.

A benefit of our custom injection molding services is the wide range of polymers you have access to. At TenX, we have extensive experience molding both amorphous and semicrystalline polymers. We understand different applications require specific material properties, and we offer a wide selection of materials to meet those needs. From common engineering plastics to specialty polymers, our expertise allows us to recommend the most suitable material for your project, ensuring optimal performance and durability.

Injection Molding & Tooling Services

Prototype &

Mid-Volume Parts

For quantities ranging from 100 to 100,000 parts, TenX can product parts with rapid turnaround times and precise execution. Learn More

High-Volume

Production Parts

When the need is for 100,000 to Millions of parts, TenX has the capacity to accommodate your injection molded needs. Learn More

Prototype

Tooling

Class 105 & 104 Injection Mold Tooling built to satisfy both prototypes & low/mid-volume injection molded part requirements. Learn More

Production

Tooling

Injection Mold Tool classes 103, 102 & 101 built for various levels of production; expected tooling shot life ranging from 100,000 to Millions of cycles. Learn More

UNRIVALED INJECTION MOLDING EXPERTISE AND SERVICE

Our team of skilled engineers and technicians is dedicated to delivering excellence in every aspect of injection molding. From design assistance to final production, we work closely with our clients to understand their unique requirements and provide customized solutions. With our cutting-edge technology and commitment to innovation, we are continuously improving our injection molding processes to deliver the best results.

When you choose TenX for your injection molding needs, you can expect superior quality, fast turnaround times, and exceptional customer service. Contact us today to discuss your plastic injection molding and manufacturing needs or to learn more about our capabilities.

FREQUENTLY ASKED QUESTIONS

Injection molding is a manufacturing process in which molten material, typically plastic, is injected into a mold cavity. Once the material cools and solidifies, the mold opens, and the finished product is ejected.

While plastics are the most common materials, other materials like metals, rubber, and some composites can also be used in injection molding.

Injection molding is versatile and can be used to produce a wide range of products, including automotive parts, consumer goods, medical devices, packaging, and more.

The process involves melting plastic pellets, injecting the molten material into a mold, cooling it to solidify, and then ejecting the finished product. This cycle is repeated for mass production.

A mold is a tool consisting of two halves that define the shape of the finished product. It is designed to allow the molten material to cool and solidify into the desired form.

Single-cavity molds produce one part per cycle, while multi-cavity molds produce multiple identical parts simultaneously, increasing production efficiency.

Advantages include high production rates, consistency in part quality, design flexibility, and the ability to use a variety of materials.

Challenges may include achieving uniform filling in multi-cavity molds, addressing issues like warping or sink marks, and ensuring proper cooling for complex part geometries.

Yes, injection molding can be used for prototyping, but it’s more commonly associated with mass production. Prototyping may involve lower-volume processes like 3D printing or CNC machining.

Tolerances depend on various factors, including material, part geometry, and mold design. In general, injection molding can achieve tight tolerances, often within a few thousandths of an inch.

While it generates waste material (e.g., runners and sprues), injection molding is considered relatively efficient and can be environmentally friendly when using recyclable materials and optimizing production processes.