Urethane and RTV Casting of Parts

Get a Quote

40+ years of experience

ITAR Registered

ISO9001: 2015 Certified

URETHANE CASTING SERVICES TO MEET A RANGE OF NEEDS

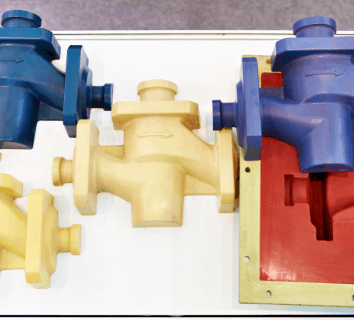

To quickly produce high-quality plastic or rubber parts without the cost of hard tooling, urethane casting is a great alternative to injection molding when annual volumes are too low to justify the mold cost. TenX Manufacturing specializes in urethane casting services, utilizing 3D printing, silicone mold-making, and post-processing capabilities to produce parts with a range of durometers and colors.

RTV MOLDING SERVICES

RTV (room temperature vulcanization) molds are created using a master pattern. The master pattern can either be created using CNC machining or a 3D printer, such as an SLA machine. Silicone rubber is poured around the master pattern, creating a cavity and a core. The master is removed once the silicone rubber sets and leaves a void into which several materials may be cast.

RTV molding is an inexpensive way to bridge the gap between prototype and production. It is most effective when you need a short run of parts to simulate production parts. More common materials used for RTV molding are polyurethanes, wax and silicone. Polyurethane can simulate a wide range of materials from soft rubber to hard plastic.

Try our variety of Urethane and RTV casting services that are adaptable to the specific project you bring to the table. With more than 40 years in business, our 80,000-square-foot, state-of-the-art facility is the place to go for your urethane and RTV casting needs.

THE CASTING PROCESS

Master

The process begins with a 3D CAD file which is used to 3D print a master pattern of the part. The master pattern is then finished to achieve the desired texture or surface finish, ensuring it accurately represents the final part’s design.Mold

Using the finished master pattern, silicone molds are created. These molds are flexible and allow for the production of complex parts. The molds can be customized to accommodate various part geometries.Parts

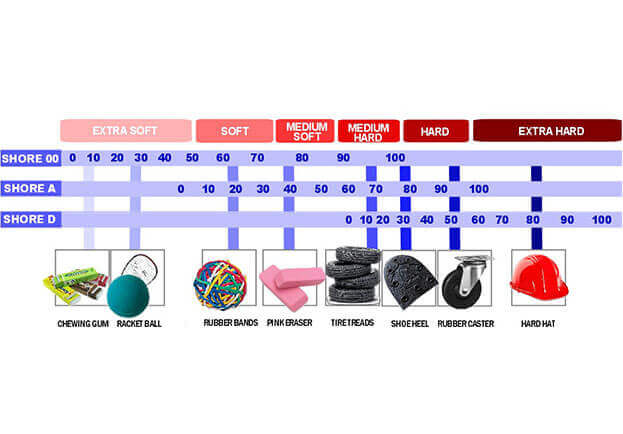

Once the molds are ready, casting begins. The molds are filled with liquid urethane or silicone materials, which cure and solidify to form the final parts. This process enables the production of parts in a wide range of durometers (hardness) and colors.HOW MANY PARTS WILL A SILICONE MOLD PRODUCE?

Generally, a silicone mold will max out at 25 parts, softer durometer parts such as those on the “shore A” scale will allow for some extra parts; optically clear parts will generally only allow for a maximum of 20 parts from a single silicone mold.

We’ve cast parts in excess of 8 feet long, 4 feet wide, and over 500 cubic inches in volume.

Yes, many times a customer only requires annual volumes of 100 parts or less. When quantities are low, cast urethane or silicone parts are a great way to fill the order, and will save substantial money when compared to traditional injection molding.